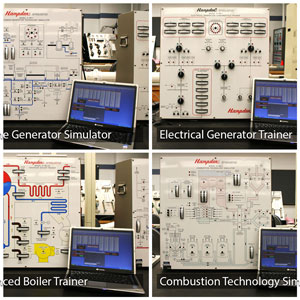

The four trainers include 1: Turbine/generator technology with high, intermediate and low pressure turbines; 2: Electrical generation with loads and synchronizing of off-line turbines with on-line turbines; 3: Advanced boiler technology with six fuel inputs, economizer and induced and forced draft; 4: Combustion technology including coal, gas, and oil.

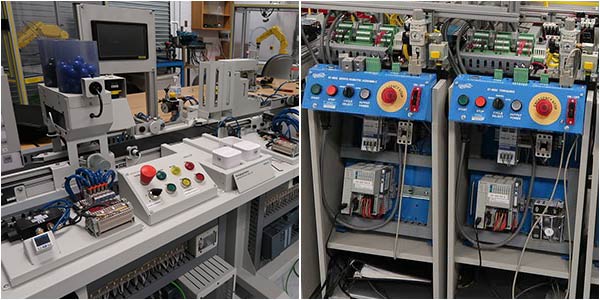

ControlLogix PLCs (Programmable Logic Control) and S-7 Siemens PLCs are used. Students build and control projects with HMIs (Human Machine Interface) using RSView and interfacing the PLCs with Motion Control, PowerFlex AC Drives, Robots, PanelView and process control systems as well as using Hart and Foundation Fieldbus protocols.

Mechatronics is an electro-mechanical field that incorporates all the basics of electrical and mechanical system that work together to make a product. Students learn each component and then how they work together. The student then gets troubleshooting experience to help the system running. We have an Allen Bradley version and Siemens version.

The calibration training starts with bench calibration using manometers, dead weight testers, and hand calibration units like current simulators and then goes to calibrating with different fluke units, emerson trex and beamit calibration. The last part includes database management of calibration where the students upload the data, do the calibration, and then download the updated data.

Associate Professor of Electrical Engineering Technology

Professor of Instrumentation